Component Shortages – Don’t Panic, We’ve Been Here Before

York Region Hardware Tech Companies: A Driving Force for ‘Made in Canada’

February 26, 2021

Microart Services and Berlin KraftWorks Partnership Connects Innovation to Production

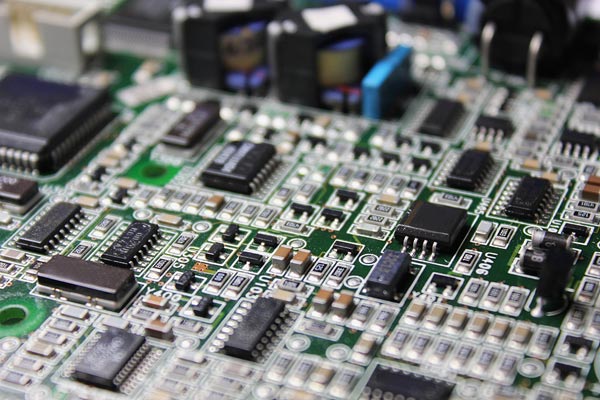

June 11, 2021After a year of disruptions, mostly as a result of the pandemic, we find ourselves back in the routine of component shortages and allocations. The media is whipping up a frenzy and even the White House is getting involved. This time the automotive industry, already hit by COVID, seems to be suffering more than most.

But don’t panic, the Microart supply chain team is on it and this is not our first rodeo, we have seen it all before and are working directly with customers and device manufacturers to secure pipelines, on hand inventory, order coverage and allocations. Collaboration and visibility make this possible. Our long term partnerships with our customers are mirrored by long term relationships and agreements with our suppliers, all backed by real-time supply chain visibility, solid forecasting and good old fashioned planning.

We appreciate that the pandemic isn’t fully behind us yet and that makes forecasting harder than ever. That’s why it is important we constantly communicate up and down the supply chain, making sure we know where our customers see demand going and where our suppliers see bottlenecks and challenges. The more order visibility we have the better we can support demand. We are driven to deliver results and continuity to our customers and to their customers, that’s why we focus on these long term partnerships, build solid inventory and flesh out contingency plans rather than trying to drive down inventory turns and reduce working capital.

We like to think it’s the right blend of just-in-time and just-in-case that delivers the win-win partnership with our customers that Microart has always strived for.

Chat soon friends!