Interview: Microart Services still growing in Canada

Microart Services – ‘moving on up’

August 21, 2013Based in the Greater Toronto Area, Canada, Microart Services began about 30 years ago as PCB design company, using hand-tape and digitizers. Eventually the company migrated to PCs. Vice President of Operations, Mike Wood, talks about the climate in Canada and how the company keeps growing.

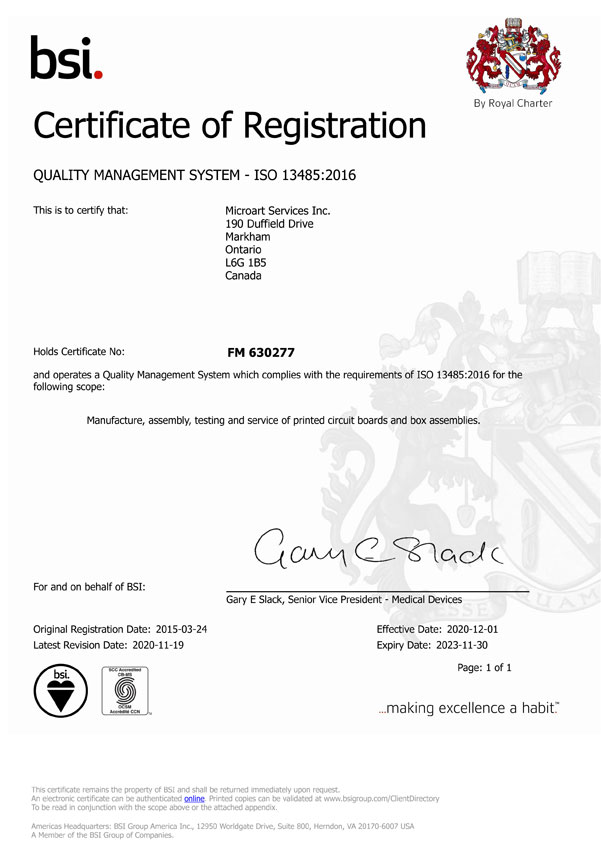

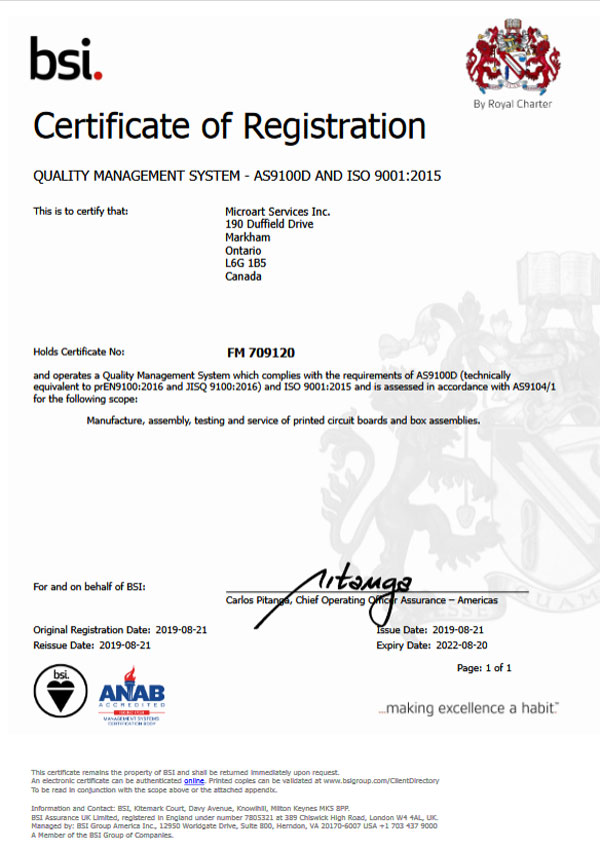

Ten years ago Microart Services purchased a small assembly shop from one of their contractors. At the time they had just one pick and place machine and about ten employees. Now, ten years later, the company has over 200 employees and five surface mount lines running three shifts, six days a week. Mark Wood, Vice President of Operations, joined the company six years ago, but has been working in the industry for close to 25 years. The Greater Toronto Area is still fairly vibrant, he says, but its seens its fair share of change over the last ten years. “A lot of the manufacturers here in Toronto were doing large volume and there were a lot of large OEMS at the time too … here we are ten years later and of course a lot of that is gone.” To survive this potentially disastrous sea change, Wood says Microart Services concentrated on smaller lines – prototypes and lower volume manufacturing. Despite the changes, the majority of the company’s customers are still geographically based in the GTA area. “There’s still a lot of the household names here, but most of what they are doing now, at least in this area, is engineering. So typically a lot of our customers we will build the prototypes and the low volume…When it goes into high volume it will be transferred offshore and we are fully accepting of that,” explains Wood. Perhaps this willingness to accept change has helped the company continue to grow over the last three years despite a economy that is less than friendly. “We believe it is just our business model of doing the low volume and quick turn,” says Wood explaining the growth. “What we are finding is that a lot of our customers, because of the downturn in the economy, they’ve had lay-off a lot of their manufacturing people so their capacity to build their products has diminished to the point where some of them only have people coming in part time.” Rather than only having those people come in part-time, companies prefer that Microart Services take care of everything, shipping directly to their customers. Microart Services aims to to ship everything within five days at the longest. Wood says a lot gets turned around in 24 to 48 hours. A diversified customer base has also allowed the company to insulate itself against cooling in once hot markets, like what they are currently seeing in the solar market. The medical industry is hot now, but who knows how long that will last? “I think that is another advantage we have over our competitors. We probably have four to five hundred active customers and we touch on every industry there is,” says Wood. The company’s biggest customer makes up 12 percent of its business. The strategy seems to have been successful – earlier this year the company took up an extra 10,000 square feet around the corner of its facility to keep up with growth. They plan to relocate to larger building in the area as soon as possible.

Published Evertiq Magazine May 04 2012